Division I works on how to improve and optimize the safety, the performance and the durability of facilities or materials for nuclear and thermal power plants. The high-temperature and high-pressure aqueous environment is an important increasing factor for degradation of these materials. Whatever the material used, they are altered more or less with serving time on contact with the environments. Accurate and reliable knowledge of the behavior and properties of the materials over their lifetime in environment is required for plant safety.

Research Areas

1.Performance evaluation and life assessment of structural materials for nuclear plants

2.Corrosion, stress corrosion cracking, corrosion fatigue and flow-accelerated corrosion of nuclear materials in high temperature and high-pressure water

3.Service safety evaluation of structural materials for ultra-supercritical thermal power plants

4. Creep behavior and mechanism of heat resistant steels

5. Fretting wear and fretting corrosion of engineering materials

6. Grain boundary engineering for metallic materials

7. Environmental failure mechanism and numerical simulation of metallic materials

8. High throughput test and characterization technology for material service behavior evaluation

Research Highlights

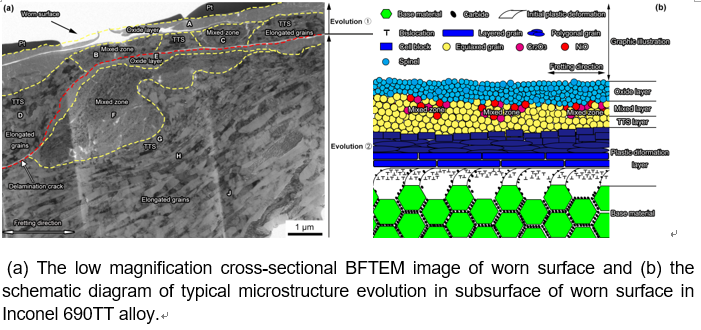

1.The fretting wear behavior of Inconel 690TT and 600 alloys in different environments were studied. The fretting running characteristics, coefficient of friction and wear volume, gradient structure evolution and crack initiation and propagation in the worn subsurface induced by fretting wear were analyzed. The models of formation of gradient structures in different environments were established.

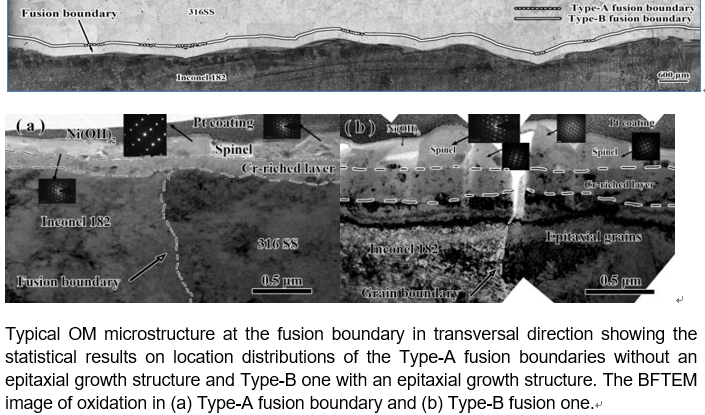

2.Microstructure and corrosion behaviors of dissimilar metal welds (DMW) A508-III/Alloy 82 and SS316L/Alloy 182 for nuclear primary pipe.

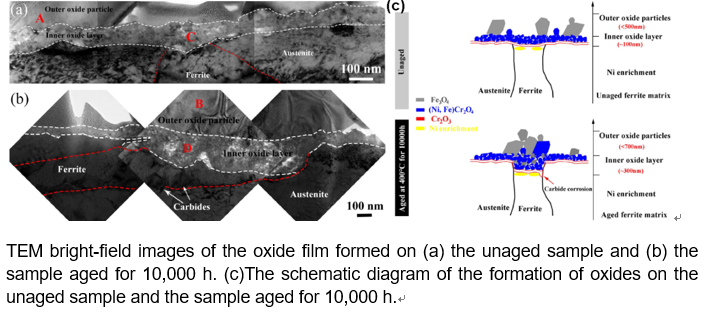

3.The microstructure, thermal aging behavior of nuclear grade 308L cladding material and their effects on the oxidation behavior in high temperature water.

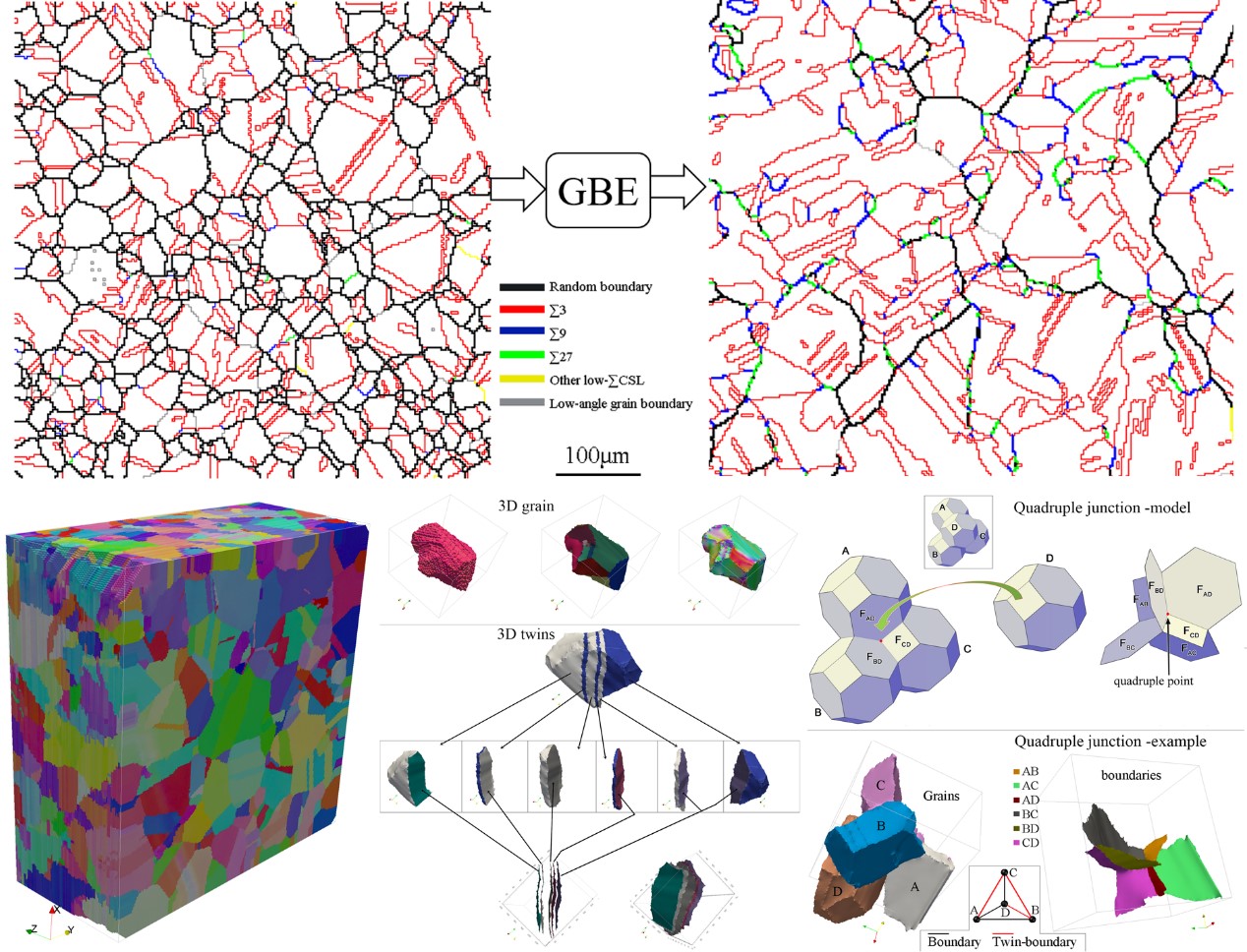

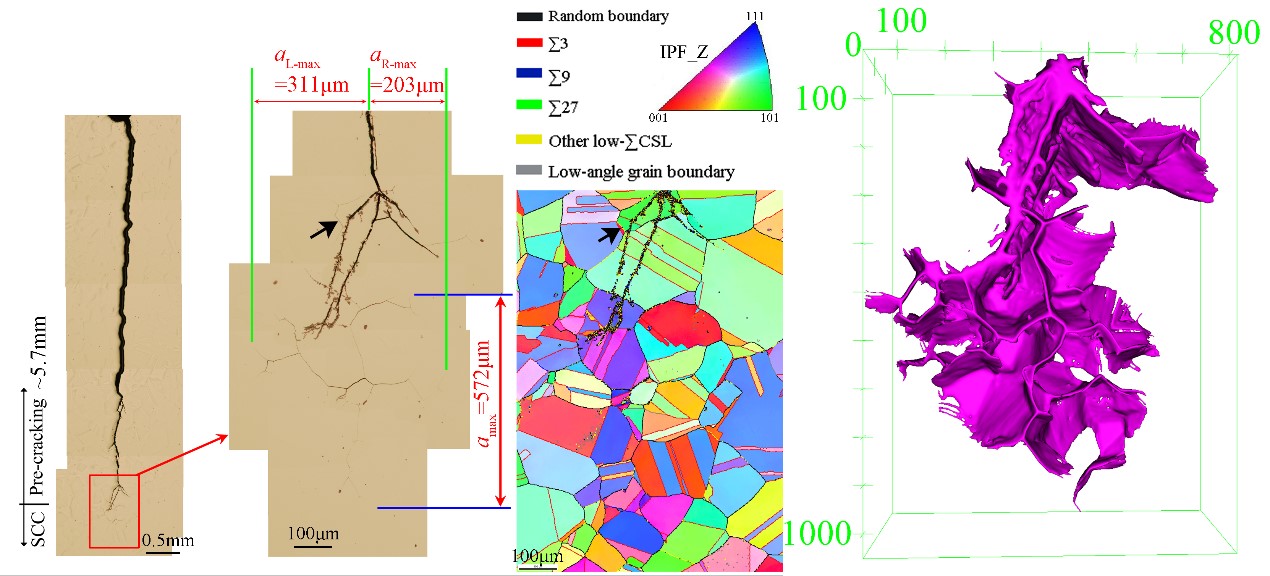

4.Grain boundary engineering (GBE) for improving grain boundary related properties of Ni-based alloys and austenitic stainless steels for nuclear reactor applications. 3D characterization of microstructures for investigation of the 3D grains, grain/twin boundaries and grain boundary networks.

5.Grain boundary character distribution and its effects on intergranular stress corrosion cracking of austenitic stainless steels in high temperature water, and 3D characterization of intergranular cracks.

Team members